The Hobie Outback is designed from the outset to allow the fitment of Hobie’s own Sailing Kit. I’m certainly not a big fan of sailing, though I really like the idea of being able to utilise a sail to enable me to travel further with ease and to perhaps fish marks that I’d not previously considered. The Hobie Sail Kit is a fairly basic affair and consists of a two piece aluminium sail mast, the sail itself and a control line. The complete setup breaks down and stores in the durable bag that is comes with. The sail is available in four colours, red, white, blue and yellow. I opted for the red to match the colour of my Outback.

Rigging the kayak for sailing is a simple enough affair. The sail slides onto the extended mast and the mast is then inserted into the sail mount just behind the front hatch.

Officially the control line is passed through the pad eye at the rear of the kayak (lifting handle location), back through the seat buckle(either side of the seat) to provide the kayaker with hand control. The sail itself is quite large, achieving a height of 2.6m (3.1m if you include the mast) with a sail area of just under 2 square metres.

I

I

Having tried the suggested rigging method, as mentioned earlier, and I didn’t find it particularly ideal for a few reasons. The rear pad eye created a lot of friction on the control line and added additional effort when adjusting the sail. The control line crossed the rear tank well due to it passing through the seat buckle, hardly ideal when you have a crate or dry box fitted for fishing purposes. The other point I disliked was that the control line needed to be pulled forward to tighten the sail, whereas it would feel more natural to pull it back towards you.

The other potential downside is that the sail cannot be easily stowed (furled) when fitted to the kayak. A couple of years ago I’d seen some videos on You Tube showing a homemade furling device for the sail, this was something that I was going to copy to make the sail more user friendly.

After visiting the garage several times over a two day period I decided on a plan of action. The sail control line would be re-routed using low fiction pulleys ensuring that it was sufficiently clear of the tank well and whilst permitting a more ‘logical’ control. I visited the local chandlers and picked up some initial supplies.

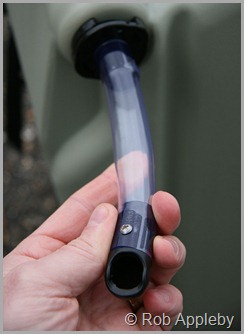

A simple furling system would be constructed as per existing ideas available on the internet. A quick visit to the local plumbers supplies saw me return home with some 1.5” downpipe and appropriately sized end connectors. I decided to tweak the existing YouTube design by inserting a narrower tube within the PVC pipe. I thought it may be better at spreading any potential loading and wear.

The photograph below shows the basic parts that make up the furling device. Two modified end caps, the PVC pipe and the fibreglass inner guide. Marine Goop was used to glue the parts together. I’m not going to cover this in any detail as there are already a couple of very good videos on You Tube that show the construction and operation of the furling device.

What I will say that it’s very cheap and simple to make whilst being highly effective. Having the ability to furl the sail whilst afloat is highly advantageous making this a must have modification. The photo above of the furling device is an early trial setup. The finished product had a longer rope fitted enabling the sail to be locked off using the zigzag cleat that was originally fitted for the anchor setup. The furling device was also connected to the sail using a small carbine.

To furl the sail it’s a simple case of pulling on the furling rope whilst maintaining a little tension on the main sail control rope. The sail will, with a little practice, furl up tightly and can be easily locked into place to prevent the sail unfurling whilst afloat as required.

With the furling line completed and functionally tested I turned my attention to sorting out the routing of the control line for the sail. I wanted a sailing system that would attach and detach from the kayak very quickly, one that was effectively one piece and did not consist of any loose parts. To alleviate the friction issue of the control line passing through the rear pad eye, I fitted a Harken block to the pad eye using a carbine.

The difference was enormous, with very little effort being required to move the sail. The next issue was the routing of the control line around the tank well area. I’d previously fitted two small pieces of GearTrac 175 on either side of tank well to act as mounting points for my navigation light, monopod camera mount, etc. As it happened the GearTrac was ideally placed to overcome the routing problem. I mounted another Harken pulley onto the GearTrac using a YakAttack T-Bolt and knob. It turned out to be a very simple and effective solution.

Note that both the Harken pulleys used to date and of the ‘closed’ variety, i.e the rope cannot jump off the block, the rope runs through the blocks. This has a couple of advantages, the obvious one being that the rope will remain on the pulleys at all times. This not only ensures that the rope remains in place during normal operation, it also means that the pulleys will remain attached to the rope when the pulleys are disconnected from the kayak.. all part of the plan.

The final issue was the routing of the control line to the cockpit of the kayak. I wanted to be able to reverse the direction of the control line as mentioned earlier to produce a more natural operation, I also wanted to be able to lock off the control line as required.

After some head scratching I found myself looking at my box of YakAttack bits. I already had some GearTrac mounted either side of the cockpit to permit the mounting of a fish finder/GPS, cameras, etc. The YakAttack Mighty Mount is designed to fit onto the GearTrac and can be locked in place using a T-bolt and knob. I was able to mount another Harken block onto the Mighty Mount by passing the T-Bolt through the mount and block. There was still sufficient thread on the T-bolt the permit the setup to be secured to the GearTrac. Steve at HobieCat in Poole kindly supplied me with a small cleat that was perfect for the job!

Below are photos showing the parts required for the control line reversal and lock-off modification as well as the finished product.

That effectively completed the routing of the control and furling lines, the photos above and below showing the finished routing results (the furling line below is shown in the earlier design phase with a short rope)

On refection, I’d wanted to create a modified system that provided less friction and better routing of the control ropes. I’m really pleased with the improvement in those areas, it works a treat. The furling system is superb, a must have.

The other requirement was that the sail system could be removed complete with pulleys and be fitted again in a couple of minutes. The furling device takes seconds to fit/remove and all pulleys remain attached to the control lines once removed. It’s a really neat setup and works well.

The complete setup slides straight into the original bag, perfect!

I’ve already been sailing with the Outback and despite the winds being light it was fun and the modified sailing system worked extremely well. More details and video of that first sailing experience to follow soon!