If you’ve not yet read Part 1 of the trailer build, you can view it here: Part 1

I’ve been steadily busy with the trailer most weekends since my last post, managing 2-3 hours here and there. The main achievement was getting the kayak bars TIG welded into place. Cheers to Jim for finding the time to deliver the trailer to my welding contact whilst I was working away in Somerset. The guy really does do a top notch job at welding, the bars could easily be used to lift the trailer, exactly the sort of strength and quality of build that I was looking for.

I decided to cover the bars in foam lagging, secured in place with ty-wraps. Once in position two layers of heavy duty black masking tape provided a durable top layer, and an easily replaceable one at that. This was the same construction as used on my car rollers bars.

Below is a photo of how it was left in part 1

Now with the bars TIG welded into place and suitably covered…

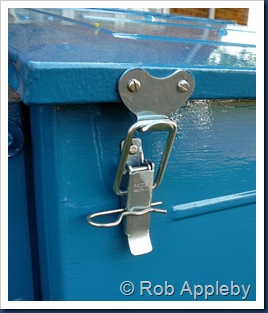

I’d attached latches to the lids and fitted stainless R-pins. I since added small lanyards to these pins to help prevent inadvertent loss. It’s the small details that count.. honest !

When I’d extended the drawbar the 50mm steel box section was bolted below the front A-frame, whereas before it’d been mounted above the A-frame. This resulted in the trailer having a slight nose-up attitude, this would only worsen as the trailer was loaded. I decided to bolt an additional short section of 50mm box the to upper side of the drawer box effectively eliminating this problem.

I took this opportunity to fit hardened tamper proof covers to the hitch bolts for improved security. I also wanted a connection point close to the tow hitch to allow the trailer to be secured to the vehicle, or when not it use to a strong point of some description. This was achieved by fitting oversize stainless ring bolts to both the trailer and the vehicle tow hitch.

Note the slot in the trailer tow hitch, this was required to allow the hitch lock to fit correctly post the fitment of the additional section of 50mm box section to the upper side of the trailer tow bar. It was quite a tedious job to slot through the hitch and box section, though the end result was worth the effort.

The trailer has been lined out with removable 3mm rubber matting to provide a non-slip floor and ultimately to provide protection to the paintwork. The lockable cupboard was lined with the same material, as was the top surface of the cupboard to provide a convenient working surface when the trailer lid is opened.

The trailer had initially been overly nose heavy (62lb at the hitch) post the fitment of the extended drawbar. I overcome this issue by doing two things. Firstly I fitted the spare wheel internally and to the rear of the trailer. This provided security for the wheel itself whilst moving the trailer balance point further aft. This wasn’t enough by far so I decided to bolt a steel double jerry can holder within the rear of the trailer, which with a single container of water balances the trailer up nicely. The spare wheel is secured to the jerry can holder with a shortened roof strap, simple and effective!.

Being able to carry water or fuel safely within the trailer can only be a good thing. Whether is be water for camping, or merely for rinsing the kayak/equipment off post a trip. Clearly there will be kayak/fishing equipment to be loaded as required and positioning this suitably will provide a nicely balanced trailer.

I designed the trailer to be able to carry 2 large kayaks face down, side by side. However, with the use of J-bars it would be more than capable of carrying 3-4 kayaks. I’ve clocked up a few miles driving around locally with a trial on the highway and I’m more than pleased with the result.

As can be seen from the above photos the kayak can be easily and quickly secured to the roof bars. Fitting a security cable through the scupper holes and trailer lifting ring provides peace of mind against theft whilst in filling stations, camping, etc.

I still have a few further improvements in mind, though I’m planning to use the trailer for a few weeks before carrying out any further modifications. Cost to date is around £350, certainly no more than £400, which I reckon is an excellent price considering the final result.

I’ve since made better use of the lockable cupboard space by adding a set of drawers. At the top is a sliding shelf to which I’ve fitted a 2 hob gas burner Not shown in the photos), the butane bottle being situated and secured within the main trailer storage space. The two drawers can be used for the storage of food, bottled water, pot, pans, etc, etc.

I think that’s about it where modifications are concerned. The trailer has only seen action on a couple of occasions where it performed well, no complaints.

3 comments:

Nice job Rob..... but I reckon that jerry can is more likely to be filled with cider ;o)

Still, as long as it balances out the weight distribution who cares!!?

This is very true!.

As it happens kayaks with a rudder are tail heavy. With the kayak/s on the trailer with the rudder/s to the rear the trailer balances up fairly well, too well perhaps. Some nose weight is a good thing for stabilty. Well chuffed with it, it should see action in the next week or so.

thanks for the tip. I will put those to my two blogs and hopefully it will work. Ill be back to post some update.

Post a Comment