It’s been quite a while since I’ve had a ‘blank canvas’ to work with. I’ve rigged several kayaks in the past few years, though it’s been a couple of years since my last rigging exercise. I’d received a Hobie anchor trolley kit from the Hobie Centre in Poole and was eager to get to work. An anchor trolley permits the user a lot of control whilst using an anchor, drogue or stake out pole. The direction of the kayak can be positioned to suit the weather, tide or the anglers particular requirements.

The kit itself is comprehensive with a decent set of instructions, though these can be tweaked to suit a particular model of kayak.

I should point out that it’s a universal kit as are in instructions. A good amount of thought needs to be given as to how best to position the various items of hardware. When it comes to drilling holes in a kayak it’s very much a case of think several times prior to drilling, mistakes are not always easy to rectify!

Both sides of the Hobie Outback are very similar, with regards to fitting an anchor trolley it’s a case of use the side which best suits the individual. I went with the left hand side as it’s the side I’ve anchored from for the past five years, no need to change something just for the sake of it.

The kits comes with two pulley blocks, one to be positioned forward, the other aft. Ideally the blocks should be positioned as far forward and aft as reasonably possible, normally within 12” of the bow and stern. This allow the kayak to lie ‘correctly’ with the tide when anchored. With the pulleys mounted further inboard, the kayak will tend to lie slightly across the tide. It’s always advisable when drilling holes to place them above the waterline. As much as I always apply suitable sealant to any hole there’s no point in tempting fate. If a seal fails and a leak occurs, water ingress will be minimised when positioned above the waterline.

Quite of a lot of the fittings on the Hobie are screw-in fittings, in the case of the later Outback models this includes the paddle holders.

The paddle holder fittings can be removed by simply unscrewing them. One was easy to remove, the other proved to be rather difficult, though it was quickly removed with the careful use of some vice grips.

The kits comes with two screw-in pad eyes which are fitted in lieu of the fitting just removed. These take seconds to fit and provide a very neat finish.

I really cannot stress enough the importance of trial fitting the trolley and your proposed location prior to drilling holes and affixing the hardware to the kayak. I used strips of black masking tape to hold the pulleys in place whilst trying out a few potential mounting options. I finally settled on a locations for the pulleys and the drill was finally powered up!

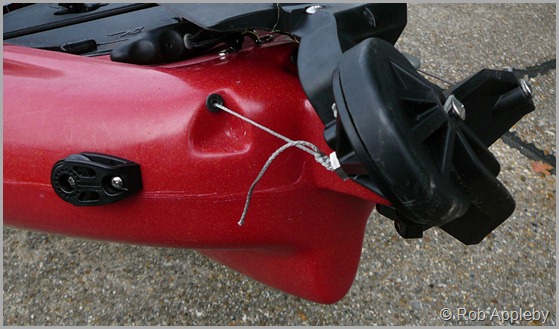

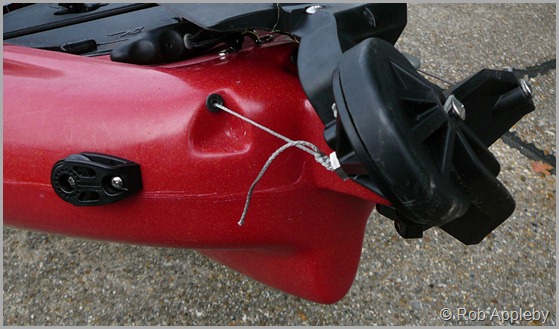

With the rear pulley positioned, I drilled the first hole straight through the pulley mounting hole, loosely fitting the first bolt on completion. With the first bolt holding the pulley in place the second hole was drilled through the pulley mounting hole. This ensures that both holes are accurately drilled.

The photo above was quickly taken for illustration purposes only, for the eagle eyed folk out there, I am indeed holding the pulley back to front!. With a small amount of sealant (I used Marine Goop) applied to the mounting holes the pulley was fixed in place using the nylon locknuts, bolts and oversized washers supplied in the kit.

Should access to the bow or stern of the kayak be too difficult to permit the use of nuts and bolts the Well Nuts supplied with the kit can be used. This wasn’t an issue on the Outback as this particular model has a large round hatch at the rear and a large forward access hatch. I’m personally not a fan of Well Nuts and was pleased that they weren’t required.

The same procedure was repeated for the front pulley and within five minutes it was bolted in place.

The trolley line was then threaded through the pulleys and screw-in pad eyes. The lower trolley line passed through the screw-in pad eyes fitted earlier. The upper line is the main control line and features a stainless ring to which I can attach my anchor setup as required. The kit comes with a plastic hook, though I prefer a stainless ring, personal preference at the end of the day. A length of supplied bungee cord was fitted to one side of the stainless ring, this ‘softens’ the effects of the kayak riding in a swell and reduces the likelihood of these movements pulling the anchor free whilst providing a more comfortable experience for the angler.

I’d purchased a zigzag cleat and incorporated this into my trolley design. It’s an important piece of kit when anchored in tide. If the trolley inadvertently moves whilst anchored in a strong tide there’s the potential for the kayak to become unstable and potentially capsize. The zigzag cleat allows the trolley to be suitable locked in the required position. The cleat itself is rather bulky to be honest and I’ve broken one before whilst loading a kayak on the roof of my car. The Hobie Outback features recessed storage on either side of the cockpit area so I chose to mount my cleat in the forward recess. Access to the ‘up’ rudder toggle isn’t particularly obstructed when the trolley line is locked off, though to be honest there’s no reason to use the rudder toggle when anchored.

With the pulleys positioned well forward and aft the upper control line had a strong tendency to ride up the side of the kayak and encroach into the cockpit area. I found that rather annoying and untidy so I fitted a bungee button in between the screw in pad eyes to provide a neater solution.

That effectively completed the anchor trolley installation. I’ve ordered an aluminium cleat which I’ll position forward in the cockpit to aid anchor recovery in a strong tide, though I’ll cover that in a short article sometime soon. Below are a few ‘before & after’ photos of the completed anchor trolley installation, fitted to suit my own taste. There are of course various design possibilities, though it’s worth taking your time, thinking of you requirements, sitting in the kayak and testing out your chosen design before taking the plunge and bolting everything in place.

‘Before & after’ photos

![P3040967[5] P3040967[5]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEg7LG1ndzAt1HSUO93Rq88sDf7rSniZn2fhHPIMS0dyMGcSaUoJkRMynm2rmWjHp10Sa6uTbVjv4qppjCpNysIm9mwOIrj42ai1yMh5KeICXDurrFTLIzoMUIQP80qO0tV2nwqLyzGR2WDV/?imgmax=800)