I’ve been absolutely itching to get out and wet a line as of late, though due to a combination of work and bad weather it just hasn’t happened. That said, I hope to hit the water within the week, fingers crossed.

A good few months ago, might even be over a year now, I purchased a couple of Shimano Charter Special 1000 LD lever drag reels. One was brand new, the other was purchased locally for a great price. They retail for over £100 which is reasonable money for a reel of this design and quality. I was incredibly lucky as I picked up one as an unwanted gift for £50 and the other for considerably less!. The used reel was in excellent condition though the drag wasn’t particularly effective. When I collected the reel the drag was locked down hard. If it’d been regularly stored like this, it’d certainly have damaged the drag washer.

The original washer is a canvas type washer, though the fibre washer from a Penn HT-100 (part no. 6-5600) is virtually a direct replacement. I purchased a few of these washers from Mikes Reel Repair in the USA. They’re a great company to deal with and the parts arrived within a few days.

The whole job of replacing the drag washer and re-lubricating the reel takes an hour or so. No specialist tool were required, a couple of screwdrivers and a small adjustable spanner is all that was required. Oh, a ‘Dremel’ type tool would be advantageous, if you haven’t got one now’s the time to pester your friends!

So if you haven’t seen one before, here it is, the Shimano Charter Special 1000LD. The schematic for this reel can be found here.

The first step is to strip the lever drag assembly off the reel. The cap on the lever assembly unscrews, releasing the cap and spring directly below. Beneath the cap and spring is a plastic lever shaft body which will either fall out or might need shaking out (take note of which way up it is fitted!). The drag lever can then be removed followed by the thrust washer directly behind the lever.

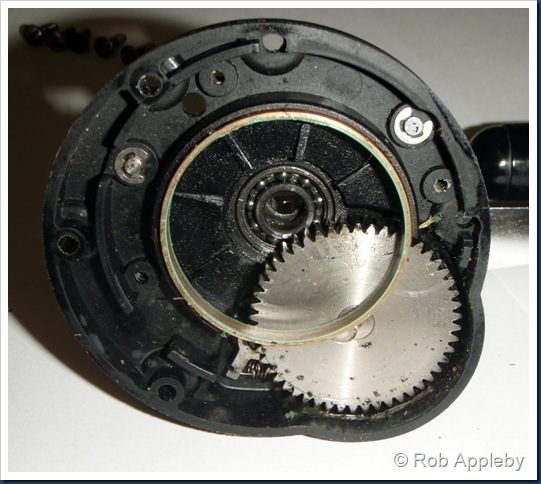

The polished metal lever quadrant and three screws can now be removed. You should end up with the reel as shown below.

The five screws that secure the side plate can be removed, followed by the side plate itself.

Note the two small blue brake blocks attached to the spool assembly. I removed them at this point as they’re highly likely to fall off and be lost at some point during the overhaul. One thing that was very apparent at this point was the lack of grease within the bearings, very disappointing.

This was rectified during the overhaul process. I used a marine grade grease that wont emulsify when in contact with water. It also contains corrosion inhibitors, etc.

The spool assembly slides out from the main reel body as a complete unit. Loose line makes removal a little fiddly so best to keep it taped down and out of the way.

Any exposed gear wheels and shafts need to be lubricated with grease !

The spool cap (with a ‘toothed’ edge) unscrews exposing the drag washer.

NOTE: it is a left hand thread. There was arrows on mine showing direction of rotation for removal. The caps on both my reels were incredibly tight resulting in my having to lightly clamp the spool in a soft-jawed vice to aid removal.

The closed bearings (visible above) were removed and placed on a piece of kitchen towel. Oil placed on top of the bearing is pulled through the bearing and onto the towel. It’s a quick and effective way to get oil into this type of bearing.

The original drag washer was carefully lifted out. The replacement Penn washer has a smaller diameter centre hole. Mark the required hole diameter up with a permanent marker pen by using the old washer as a template. I used a small tapered cutting bit in a Dremel tool to open up the centre hole to the desired size. Once done it’s a simple case of fitting the new washer.

The other end of the spool houses the clicker assembly. By removing the four screws the clicker assembly and main shaft can be removed. There are two further bearing housed within that require oiling.

The main reel body can also be greased at this point as required.

Assembly is now the reverse of the above stripping process.

When re-inserting the spool, ensure that the cross pin is fitted and centralised. Check for correct alignment prior to lowering back into the reel body. There is a slot to align this pin to, if you hadn’t noticed this look back a few photos (Don’t forget to fit the brake blocks). The end plate and five screws can now be re-fitted.

When re-assembling the lever drag itself, place the lever arm into the ‘free spool’ position. The plastic circular lever shaft body should drop into the lever and mate up correctly into the slot.. Re-attach the cap & spring and you should be finished.

That’s basically it. The first reel took an hour or so, the second about thirty minutes. I upgraded the drag washers in both to the Penn items and fully lubed all the bearings and level wind assembly. The handle itself can also be removed and a little oil dribbled down onto the shaft if you so wish.

That’s my Shimano reels ready for another couple of seasons.

1 comment:

Rob,

Nice tutorial! Do quite a bit of fishing myself, and I'm looking forward to perusing your archives.

Holiday Greetings from Afghanistan!

Here is wishing you all the very Merriest of Christmas, and the Happiest of New Years!

Best Regards,

Albert A Rasch

Albert Rasch In Afghanistan™

Post a Comment